Smart 3D camera family rc_visard offers 3D machine vision with flexibility, ease of use

Low system costs, quick implementation, and a high degree of flexibility in use; this is what the rc_visard product family of smart 3D cameras promises. With an integrated processor and application-specific software modules on the camera, the rc_visard provides independently operating 3D machine vision and can therefore also be used very easily as a 3D stereo sensor. Processed 3D information such as pick points are forwarded from the rc_visard directly to the robot application.

It is configured via a user-friendly web-based user interface. The connection to a PC for further processing of the data is also possible. Via the GigE Vision interface individual 3D applications can be created based on the camera data.

The camera models measure up to 1.2 million 3D data points and achieve frame rates of up to 25 Hz depending on the resolution. Various robot interfaces are already integrated for communication between robot and camera.

Features

-

Quick implementation and easy to use thanks to user-friendly web-based user interface

July 22-23, 2025

Hyatt Regency, Minneapolis, MN

-

High application flexibility thanks to optional software modules and GigE Vision interface

-

Low system costs and high system reliability with on-board processing and application-specific software modules

-

Increased productivity thanks to smart software modules

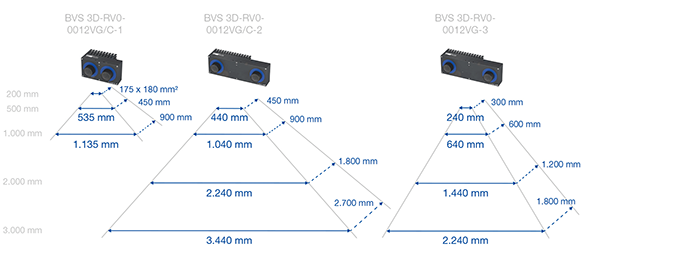

Working range

Output data

-

Processed 3D information: Gripping points, object dimensions, load carrier position, load carrier fill level

-

Camera data via GigE Vision: left and right camera image, depth image (disparity image), conference image, defect image

.png)

Leave a Reply