OptiX: Revolutionizing Inline Visual Inspection with Software-Defined Optical Imaging

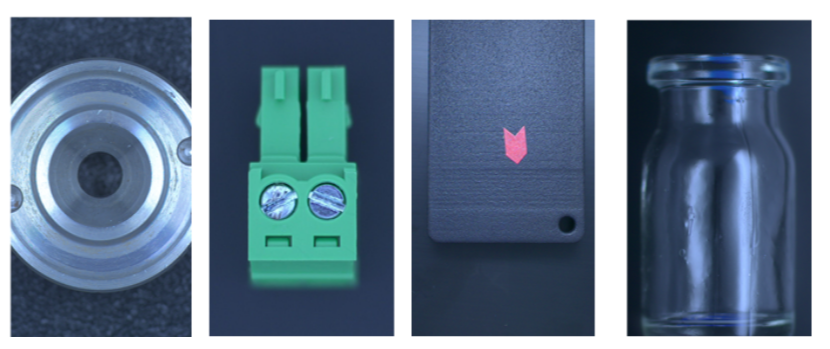

In modern manufacturing, achieving precise and high-speed visual inspections is crucial to ensure product quality. OptiX, a Software-Defined Optical Imaging System by UnitX, is designed to meet the evolving needs of industries by delivering unparalleled accuracy and speed in inline inspection. OptiX dynamically illuminates and images parts in real-time, capturing high-contrast images of variable parts, materials, and defects.

Key Features & Selling Points:

1. Versatile Lighting Dome

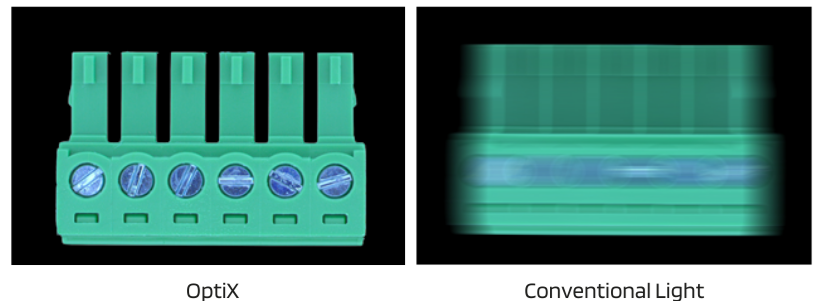

OptiX's innovative lighting dome features 32 independently controllable light sources, offering a 75-degree incident angle range. With the ability to generate 50 lighting patterns per second, OptiX enables manufacturers to adapt to complex materials, surfaces, and production requirements, ensuring optimal defect detection even in the most challenging environments.

2. High-Speed Imaging

OptiX is engineered to handle high-speed production environments with ease. Its fly capture speed reaches 1.0 meter/second, allowing for real-time image acquisition while inspecting up to 1,800 parts per minute. Furthermore, OptiX’s lighting system is 100x brighter than conventional lighting, ensuring high-contrast images that enhance defect visibility and accuracy.

3. Rapid Deployment & Adaptability

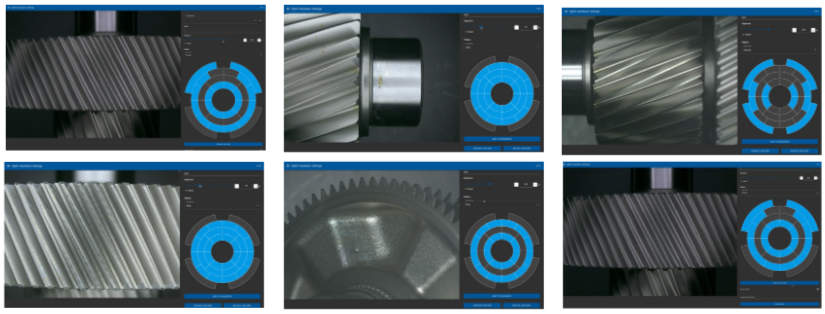

With OptiX, manufacturers can adjust and optimize their lighting parameters quickly. Through an intuitive, user-controlled software interface, operators can configure lighting settings in just minutes, ensuring a seamless transition to new parts or environments. This capability dramatically reduces downtime and accelerates production ramp-up.

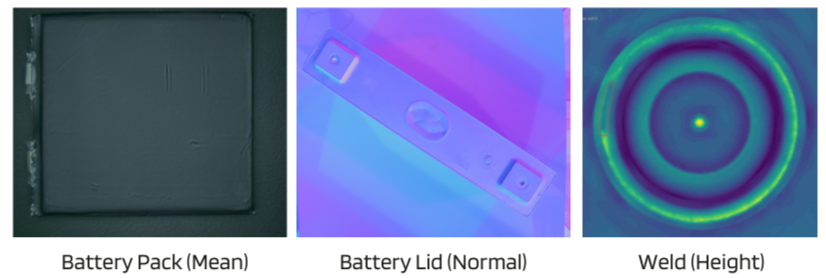

4. 2.5D Imaging Technology

One of OptiX’s standout features is its 2.5D imaging technology, which enables high-speed defect detection with depth information. Using a single CMOS area scan camera, OptiX captures depth defects with 3um z-repeatability at a 500mm FOV. It performs six 3D reconstructions per second at 5MP resolution, ensuring precise and fast depth-dependent defect detection.

July 22-23, 2025

Hyatt Regency, Minneapolis, MN

Why Choose OptiX for Your Production Line?

OptiX combines state-of-the-art software-defined lighting with 2.5D imaging to provide the flexibility and speed manufacturers need to maintain high-quality standards in fast-paced production lines. With rapid deployment, dynamic lighting control, and the ability to detect even the smallest depth-related defects, OptiX is built for industries seeking to enhance their inspection capabilities while keeping production rates high.

Optimize Your Production with OptiX

Whether you’re in the automotive, electronics, or consumer goods sector, OptiX offers a modular and scalable solution for high-speed, high-accuracy inline inspections. The ability to quickly adapt to new parts and materials ensures your inspection systems can grow alongside your business and production needs.

Experience OptiX in action and see how our software-defined optical imaging system can take your manufacturing process to the next level of quality control. Reach out today to schedule a demo or learn more about how OptiX can revolutionize your inspection systems.

For more information, please

- visit our website https://www.unitxlabs.com/optix

- contact us via email [email protected]

- Drop a visit of the Booth #6702

- Book a booth demo

.png)

Leave a Reply