Building the Future: How Robotics Is Revolutionizing Construction Through Automation

The construction industry, long dependent on manual labor and traditional methods, is now experiencing a significant transformation through the integration of robotics and automation. This change is motivated by the requirements to address labor shortage, high injuries, delayed projects and the need for higher efficiency, greater accuracy and cost savings. Robotics is accelerating the construction process and improving the quality of the result.

The Emergence of Construction Robotics

In construction, robotics is the use of automated tools to complete work that was done only by people before. You will be expected to do tasks such as bricklaying, pour concrete, conduct excavation, destroy buildings and assemble structures. Integrating robotics helps businesses handle more work, maintain safety on job sites and always deliver strong and consistent outcomes. Robotics is increasingly used by firms and innovators in construction to automate difficult and frequent tasks. Cemex Ventures states that robots are now being applied to oversight of vehicles and equipment for operations such as earthwork, moving materials, lifting loads, pouring concrete and cleaning construction areas. Besides, robots are making important contributions to disposing of waste, automated tasks and building factories outside cities. 3D printing lets buildings be created layer by layer which saves both time and waste. Though construction robotics is still in its early stages, there is a great deal of potential. It is set to make the construction process more eco-friendly and advanced which will be a great improvement to the industry. Nevertheless, high first costs, fitting new robots with existing systems and having trained operators are still problems. These issues aside, construction is headed toward greater automation and robots will take on major roles.

Key Robotic Technologies in Construction

Using robots in construction is improving the way projects are handled by eliminating certain jobs, increasing safety and boosting efficiency. Here are a few of the latest robotic technologies making a big difference in the industry:1. Autonomous Heavy Equipment Self-driving machines are changing the face of big construction work. Built Robotics has designed machines that can operate themselves in digging, moving earth and other site preparations. Thanks to GPS, LiDAR, sensors and specialized software, these machines can move around on any site with ease and without risk. With its fully autonomous heavy machinery, Built Robotics is the first in the industry to be deployed in real construction work sites, making jobs easier and more efficient.

1. Robotic Bricklaying

Robots are playing a growing role in laying bricks both for homes and offices. An Australian firm known as Fastbrick Robotics has built Hadrian X—a robot that can lay more than 1,000 bricks each hour without fail. Thanks to this technology, humans are less likely to make mistakes, projects last less time and labor costs drop. February 2025 saw PulteGroup build an entire house with Hadrian X in Florida in just a single day. Reaching this stage proves that robots can make housing development faster.

2. Drones for Site Surveying and Monitoring.

Drones are now important devices for use in construction sites. Having both excellent cameras and LiDAR sensors, drones are employed for surveying sites, creating topographic maps, observing progress and inspecting safety. Managers use this real-time information from the aerial systems to monitor what’s being done, arrange schedules and catch any early issues. Building Radar says that using drones makes decisions easier and cuts down on lengthy manual inspections. By working together, these technologies are making operations more efficient, improving results and pushing the development of smart construction.

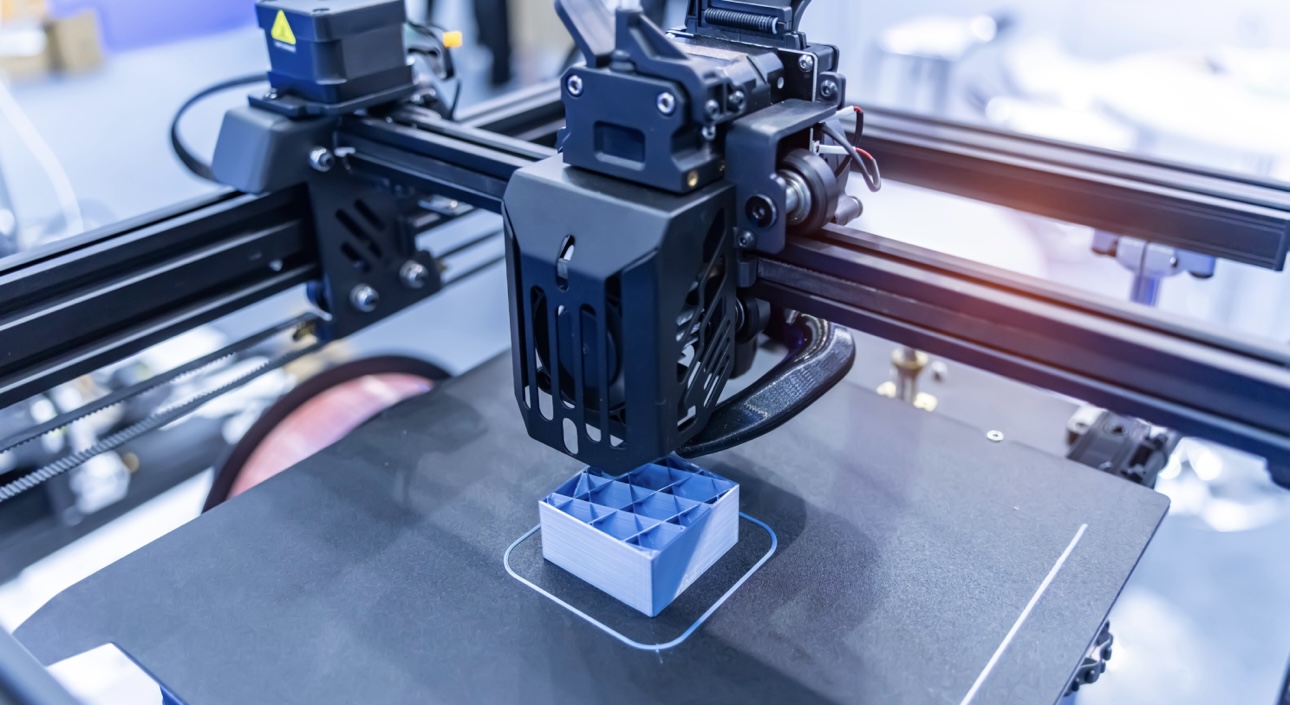

3. 3D Printing

Construction projects are able to be printed in 3 dimensions, forming components or full structures using digital designs applied in layers. By using this process, there is less waste, project costs go down and the work is finished faster.There are many architectural shapes that innovators discover because of this technology. 3D printing is seen by Cemex Ventures as an important contributor to building practices that are sustainable and efficient.

4. Robotic Inspection and Maintenance

The use of advanced sensors and AI in robots is changing how we inspect and preserve our infrastructure. Vision-based technology allows the robots to detect cracks themselves and carry out small repairs. According to arXiv, these robots help structures live longer and their use reduces risks to people and lowers spending on maintenance.

Advantages of Robotics used in Construction

Robotics in construction is helping to change the way buildings are made and organized. Efficiency and sustainability are among the main problems robotics addresses for the industry.

1. Enhanced Productivity

Thanks to robots’ continuous operations, projects can be finished faster and job completion is always reliable. Unlike people, robots can repeat bricklaying, welding and concrete dispensing with great accuracy. By doing this, fewer pricey mistakes are made and there’s less demand for additional work which helps complete the project faster.

Certified Motion Control Professional Program

Strengthen Your Skills and Enhance Your Career

Motion control is ubiquitous to automation. A3 offers the fundamental knowledge that benefits everyone working with motion control, motors and automation technologies. The program is designed to ensure professionals have the knowledge they need to advance their careers and benefit their businesses.

Motion control is ubiquitous to automation. A3 offers the fundamental knowledge that benefits everyone working with motion control, motors and automation technologies. The program is designed to ensure professionals have the knowledge they need to advance their careers and benefit their businesses.

Become a Certified Motion Control Professional (CMCP) and join the elite group of system integrators, machine builders, manufacturers, end-users and others recognized in the industry for their professional knowledge and expertise.

2. Improved Safety

Working at a construction site is not safe, mainly due to dangers from heights, running machinery and contact with hazardous chemicals. If robots are used for hazardous activities, less exposure to risk is necessary for human workers. The use of robots in hazardous environments decreases the rate of accidents and can make jobs safer, the National Institute for Occupational Safety and Health (NIOSH) explains.

3. Cost Efficiency

Although it costs a lot to install robotic systems at first, the benefits you gain over time are great. The use of robots lowers employee costs, cuts back on material loss because of exact work and speeds up the building process. Using these efficiencies on a project can lead to big savings over time.

4. Addressing Labor Shortages

The industry is having difficulties due to the shortage of qualified workers. Automating tasks with robots helps address this challenge, since those tasks may be too tough or use skills that are hard to find. According to The Times, robotics looks like a strong way to cover for missing workers and still deliver the needed products and services.

5. Sustainability

Robots help the construction industry save resources by cutting down on what is thrown away. They also help ensure that workflows use less energy which is important as more people focus on green building standards.

Challenges and Considerations in Adopting Robotics in Construction

Although robotics looks set to revolutionize construction, some matters must be carefully addressed to ensure the technology works well and is long-lasting.

1. Expensive to Set Up

The high upfront cost is a major reason why many in construction are hesitant about robotics. Set up and integration of robotics into a construction site is very costly and can be particularly tough for smaller and mid-sized companies.

2. Technical Complexity

Special skills are necessary to both operate and keep up with the complex hardware and software in advanced robotic systems. There is now a higher requirement for technicians and engineers who understand robotics. If construction companies don’t have the right people, they might not get the most from the latest technologies.

3. Integration with Existing Processes

Using robotics in regular construction work isn’t always easy. The typical approach to planning, executing and managing projects needs to be changed when using automated systems. You might need to review how you design, use different project management tools and enable human and robot teams to team up effectively.

4. Regulatory and Safety Standards

In construction, robotics has to be built and used according to the latest safety rules and industry guidelines. Having no set rules in place can stop certain people from adopting.Wikipedia notes that having clear and established rules and standards guarantees robots work safely and effectively during construction.

5. Job Displacement Concerns

Because robots are becoming more common, some are worried that manual jobs may become extinct. At the same time, automation creates more chances for work in robotic service, programming and handling data. The Financial Times suggests that the industry should help workers develop new abilities to take up these new jobs and guarantee everyone gains from the shift.

Future Outlook

The use of robotics in the construction industry is poised to increase rapidly over future years and impact building and infrastructure designs. In line with Global-IMI, the use of automation in the construction sector is predicted to grow by 85% in the next decade. Rapid growth in the industry is mainly due to the demand for rapid, secure and eco-friendly ways to complete infrastructure projects. Working AI and machine learning into construction robots is expected to make them much more functional. Because of these technologies, robots will be able to do more difficult jobs such as making real-time decisions, solving adaptable problems and moving around on sites in motion. Cobots are becoming a popular area because they are easy to work with alongside humans. They are built to help human workers do their jobs better, not to replace them and create a more connected team. There is growing potential in modular and adaptable robotic systems. Such solutions can be easily adjusted to match both simple and complex projects of any scale. Being flexible will be important for robotics to serve many different construction projects, including cities and smaller homes.

Conclusion

The construction industry is set to experience major changes due to robotics which will automate vital steps in building, increase productivity and make job sites safer. Some problems such as higher prices and fears about losing jobs, have to be dutifully managed, yet the good sides of these technologies are obvious. Since AI and robotic technology is advancing, construction firms need to stay ahead by accepting and using these new tools. The construction industry is moving towards automation, more intelligence and many potential opportunities.

Leave a Reply