Non-Contact Sensing for Lithium Battery Electrode Inspection | Accurate Foil, Thickness & Scribing Measurement

The global demand for safer and higher-performing lithium batteries continues to rise, driven by innovations in electric vehicles, energy storage, and portable electronics. At the heart of this evolution lies electrode preparation, a critical stage that significantly affects battery performance and safety.

SinceVision, a leader in machine vision and sensor technology, brings advanced non-contact sensing solutions to streamline and enhance this stage of battery production. This article outlines how SinceVision optimizes key electrode preparation tasks: detecting foil remnants, measuring coating thickness, and inspecting electrode scribing accuracy.

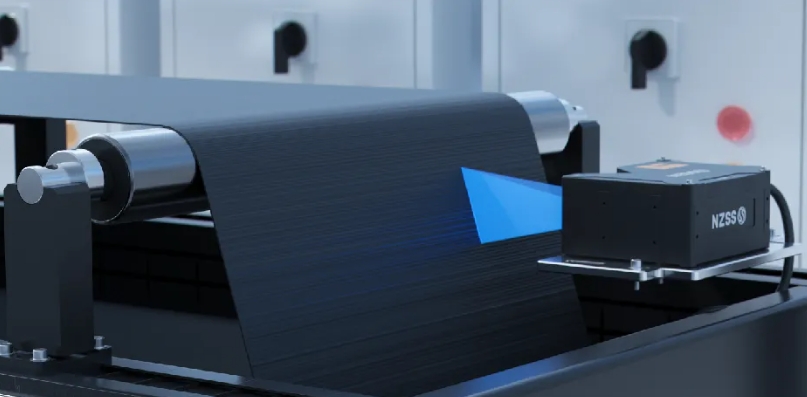

Minimizing Waste with Foil Residual Detection

Material waste during the unwinding and changeover of electrode foil rolls can lead to significant cost inefficiencies. To address this, SinceVision deploys the SR Series 3D Laser Profiler, a high-speed optical sensor designed to monitor residual foil material during the early stages of production.

- Detection Width: 288mm

- Repeatability Accuracy: ±0.1mm

- Sampling Speed: Up to 20kHz

By capturing the foil’s surface profile in real time, the system calculates the precise length of unused material. This insight enables process optimization, allowing manufacturers to reduce material scrap and improve overall utilization. It’s a practical solution that offers both sustainability and cost-saving benefits.

Coating and Calendering: Accurate Electrode Thickness Measurement

Consistency in electrode thickness is critical to the electrochemical performance of lithium batteries. Variations in thickness can lead to capacity loss or safety issues during charge and discharge cycles.

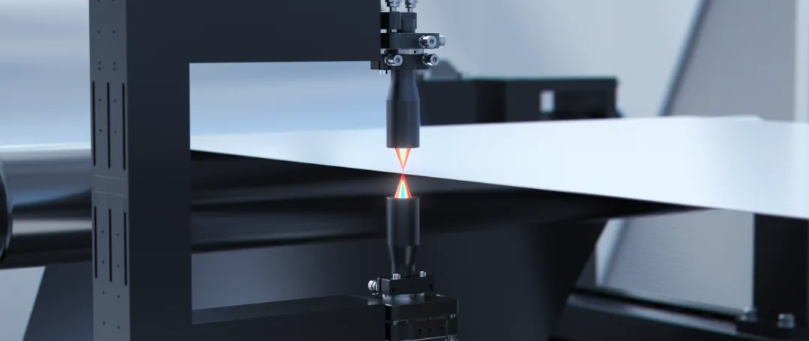

SinceVision’s SCI Series Spectral Confocal Displacement Sensor offers precise, high-speed thickness measurement tailored for coating and calendering processes:

- Measurement Accuracy: ±0.3μm

- Scanning Speed: 500mm/s

- Measurement Method: Dual-head opposing detection

Using its confocal optical technology, the SCI Series captures top-and-bottom surface measurements simultaneously. This allows for real-time detection of micro-variations in thickness. When integrated with feedback control systems, it enables dynamic adjustments to calendering equipment, ensuring uniformity across every electrode sheet.

Certified System Integrator Program

Set Yourself at the Forefront of the Global Vision Market

.jpg) Vision system integrators certified by A3 are acknowledged globally throughout the industry as an elite group of accomplished, highly skilled and trusted professionals. You’ll be able to leverage your certification to enhance your competitiveness and expand your opportunities.

Vision system integrators certified by A3 are acknowledged globally throughout the industry as an elite group of accomplished, highly skilled and trusted professionals. You’ll be able to leverage your certification to enhance your competitiveness and expand your opportunities.

Improving Safety through Accurate Electrode Scribing Inspection

The electrode scribing process creates functional grooves in coated materials, essential for controlling electrochemical behavior and preventing internal short circuits. Inaccurate scribing can lead to hazardous defects.

To ensure precise scribing, SinceVision utilizes the SR Series 3D Laser Profiler, which captures microstructural data at high resolution:

- Measurement Accuracy: ±0.3μm

- Scanning Capability: Full-field inspection with live analysis

The profiler continuously monitors the scribing depth and width in real time. This ensures consistent patterning across the electrode, reducing the risk of structural faults and enhancing the overall safety and reliability of the final battery cell.

Advancing Battery Manufacturing with Smart Inspection

From start to finish, SinceVision’s smart sensor solutions deliver measurable improvements across the lithium battery electrode preparation process. Their advanced 3D laser and spectral confocal systems provide:

- Non-contact and high-speed inspection

- Micron-level precision for both geometric and surface characteristics

- Seamless integration with automation systems

As a result, manufacturers are empowered to maintain stricter quality control, reduce waste, and meet growing industry demands for high-performance, high-safety lithium batteries.

Conclusion: Why SinceVision Sets a New Standard in Electrode Inspection

By combining robust hardware with intelligent software algorithms, SinceVision enables a new level of control in battery production. Whether you're looking to reduce leftover foil, ensure coating consistency, or guarantee safe scribing, SinceVision’s sensing technology offers dependable solutions.

These innovations are more than incremental. They're transformative for manufacturers aiming to compete in an increasingly quality-driven market.

Additional Resources:

Watch the full lithium battery application here: Lithium Battery Production: Full Scenario Applications

Email: **@*********on.com/” rel=”nofollow” target=”_blank”>[email protected]

Leave a Reply